Qui sommes-nous ?

Tor Alva: a beacon for sustainable construction

The world's tallest 3D-printed tower is not located in a metropolis, but in the middle of a remote Swiss mountain village. This unique structure shows how innovative and sustainable construction can be in the future. In a co-creation approach, BASF worked with its customer Knauf and ETH Zurich to develop the formula for the bright white mortar suitable for digital construction.

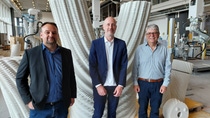

The 30-meter-high White Tower – “Tor Alva” in Romansh – was inaugurated in May 2025 in Mulegns in Graubünden. It rises like a lighthouse from the Alpine landscape. This technical masterpiece was made possible by the cooperation of three partners: ETH Zurich, which researches new techniques for digital construction and was looking for innovative approaches to developing a mortar formulation suitable for 3D printing. To this end, it contacted Knauf, a leading manufacturer of building materials, and BASF's Scouting & Academic Collaborations team in Dübendorf, Switzerland. The latter established contact with BASF specialists who had the relevant expertise, additives, and necessary production facilities.

Flexible mortar that hardens quickly

The challenge was to technically implement the architectural vision for the tower. In 3D printing, a robotic arm applies thin layers of soft mortar one after the other through a nozzle in a continuous process. This mortar must be flexible enough to bond and form continuous, uniform concrete elements, but also harden quickly enough to support the weight of the following layers.

BASF specialists researching construction additives have identified and developed potential additives that should enable these properties. For mortar manufacturer Knauf, the aim was to use these additives to produce a ready-to-use material that could be used in digital construction. These material formulations were then tested for their practical suitability in the ETH laboratories.

Once the suitable formulation for the white mortar had been determined thanks to this co-creation, the modular elements were 3D-printed by robots in the ETH Zurich laboratories, without the use of formwork. Compared to conventional methods, this saved 40 percent of material. The individual modules can also be assembled and disassembled repeatedly. This means they can be reused in a different environment.

About the Tor Alva project

Tor Alva was designed for the Origen Cultural Foundation in collaboration with ETH Zurich. It will be used for cultural events in Mulegns for five years and will contribute to the revitalization of this mountain region affected by rural exodus. The architecture pays homage to the region's former confectioners and is also reminiscent of the craftsmanship of the Baroque master builders in Graubünden. This innovation was made possible by close cooperation between ETH Zurich, Knauf, and BASF. The construction of Tor Alva was co-financed by, among others, the BASF STEP2 Incubation Platform and the JONAS innovation network, in which BASF's research department is involved.

Here you will find background information on Tor Alva.