Media

Amflora makes paper and yarn glossier and stronger

As renewable material, BASF’s genetically modified potatoes offer many benefits.

Be it potato au gratin, jacket potatoes or chips - everyone knows that there are plenty of tasty ways of eating these brown tubers. But not many people know that the potato is also the source of an important raw material for industry: starch, a carbohydrate compound. BASF Plant Science has developed Amflora, a genetically modified starch potato which only produces one particular type of starch, for industrial applications, which optimises the further processing of starch and saves energy and water.

The European Commission has now approved the genetically modified potato for commercial cultivation in Europe.

We encounter potato starch in all kinds of places in everyday life and not just in the kitchen. For instance, potato starch is used in the manufacture of textiles, paper and adhesives. Besides its versatility, starch from potatoes has other advantages too. Compared with the starch from wheat and corn, potatoes give the highest yield of starch per hectare of cultivated land. Potato starch is also of better quality than its competitors: it contains no fat and has greater stability and viscosity.

"Conventional potato starch consists of 80% amylopectin and 20% amylose," explains Dr. Thorsten Storck, a project manager at BASF Plant Science. "Many of the useful properties of starch come from amylopectin, for example its good adhesion. Amylose, on the other hand, poses a problem in many technical applications. Because it gels, it makes the dissolved potato starch unstable." Until recently this problem required a great deal of pre-treatment during processing.

So for a long time now starch manufacturers have been on the look-out for a potato that only contains amylopectin. By developing Amflora, researchers at BASF Plant Science have achieved just that. In this new potato, one of the genes involved in the formation of amylose has been deactivated. As a result, Amflora potatoes only produce pure amylopectin and no amylose. Amflora starch offers many crucial benefits for industrial applications. In paper manufacturing it makes fillers and pulp adhere better, saving both energy and raw materials. But this new potato doesn’t just deliver advantages for the processing stage; end products will also benefit from the Amflora starch. Printer paper will be glossier and yarn can be processed better. It makes concrete adhere better to the wall and keeps glue liquid for longer.

BASF Plant Science has adapted a tried-and-tested cultivation system, known as Identity Preservation System, especially for Amflora. This system ensures that Amflora cannot mix with conventional potatoes - primarily to retain the special quality of Amflora. The system covers all stages of cultivation, from the delivery of the seed potatoes to the farmer to the processing of the harvested potatoes by the starch industry.

"Amflora isn’t sold through retailers but supplied directly to farmers with whom we have contracts," explains Dr. Thorsten Storck. "The farmers growing the potatoes have to maintain minimum distances from neighbouring potato fields. Planting and harvesting machinery must not contain residue of other potatoes. After harvesting, the potatoes are transported to the starch factory where they are processed separately."Everyone involved in the process is obliged by contract to comply with the system. Tests in the Czech Republic and Germany have already shown that this cultivation system works very well in practice.

The Amflora potato variety recently received European approval and commercial cultivation will begin in 2010. This makes it the first genetically modified crop to receive this approval in the EU since 1998. An application has also been filed for the food and feed approval of Amflora, to allow the pulp to be used in animal feeding. Prior to this, Amflora was tested for several years as part of field tests in various locations in Europe. The crop was studied in detail in terms of its yield, nutrients, the composition of the tuber and environmental impact. The results were clear: the European Food Safety Authority (EFSA) repeatedly concluded that Amflora is just as safe for people, animals and the environment as any conventional starch potato.

The Prospects

Amflora will make the European starch industry more competitive. "Three quarters of the world’s potato starch is produced in Europe," says Anne van Gastel, Marketing Director BASF Plant Science. Most producers, he explains, are agricultural cooperatives which still depend on three-digit EU subsidies running. "But these subsidies will drop as from 2012, so it’s crucial for Europe to be able to produce high-quality potato starch for industrial applications."

What's more, industrial demand for pure amylopectin is existing and will persist. Experts are anticipating an annual demand of over 400,000 tonnes.

As one might expect, this also means high demand for Amflora. Agreements have already been reached with leading European starch manufacturers and negotiations with other companies are in progress. Now that EU-wide approval for cultivation has been issued, Amflora is set to be cultivated and propagated in Sweden, Germany and the Czech Republic in 2010.

The Info Box

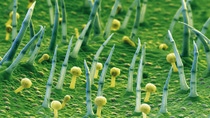

The antisense strategy - a plant biotechnology technique

The characteristics, appearance and abilities of a plant are determined by its genetic information. All of this genetic information is stored in the cell nucleus, on long molecules known as DNA (deoxyribonucleic acid). DNA itself is made up of different parts carrying information: the genes. Genes are ultimately responsible for all processes that take place in the plant, such as metabolic reactions, leaf shape and resistance to disease.

One plant has approximately 50,000 genes.

Green genetic engineering is a field of biotechnology which is sometimes referred to as plant biotechnology. It is used in modern plant breeding. Genetic engineering allows us to identify individual genes, study their function and combine them in different ways. By doing this we can breed plants with certain characteristics.

Over the last 30 years biotechnologists have developed a range of techniques and methods for deactivating, removing or adding individual genes. One of these methods is the antisense strategy, which was used to develop the Amflora potato. This process involved deactivating the gene responsible for the formation of amylose. Researchers achieved this by copying the gene and inserting a mirror image of it back into the genetic information - hence the term ‘antisense’. The copy attaches itself to the original gene, blocking it so it cannot produce any more amylose. Consequently, the potato will only produce the industrially valuable amylopectin.