Change for climate

Learning from sharks

Ever noticed how swiftly sharks move through water? We did – and we wanted to know how. When we found out, we applied the learning to airplanes. Now sharkskin technology, developed jointly with Lufthansa Technik, helps airlines save fuel and reduce carbon emissions. Call it natural inspiration.

A diver researching sharks off the Gansbaai coast.

The inspiration: the ocean’s great energy savers

Sharks are amazing. They’ve been around longer than trees – about 450 million years. And in that time, they’ve learnt how to be amazingly efficient swimmers, gliding through water with ease. But how? And can we learn from them how to help people travel more efficiently, and save fuel in the process?

We developed sharkskin technology together with our partners at Lufthansa Technik.

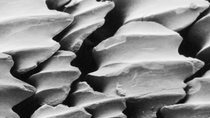

Sharks swim amazingly efficiently thanks to these tiny ‘ribs’ on the surface of their skin.

The idea: what our deep dive revealed

As is often the case, nature turns out to be one step ahead of us humans. Research reveals that the skin of a shark has lots of tiny “ribs” on it. These reduce drag and make the shark more efficient at swimming. So, why not optimize the surface of an aircraft so that it emulates shark skin? Saving fuel and cutting emissions would be an instant win for climate protection.

Sharkskin technology is being rolled out on all of Lufthansa’s Boeing 777F cargo planes and all Swiss International Airlines’ Boeing 777-300ER passenger jets.

The innovation: all about the surface

With our partners at Lufthansa Technik, we solved the problem without needing to completely redesign any planes. Instead, sharkskin technology is a simple modification – a film added to the exterior that contains millions of microscopic “riblets” (little ribs).

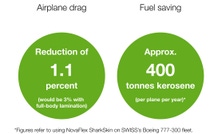

The plane becomes more aerodynamic, uses less fuel and emits less CO2. On a large long-haul aircraft, for example, it cuts more than 1,000 tonnes of CO2 emissions every year!

The impact: cutting 1,170 tonnes of CO2 per plane per year

Meet the dream team

Vjosa Schmidt, BASF’s Business Manager for Riblet Films is a big fan of sharkskin technology. “It is one of the few inventions in the aviation industry that reduces all climate-relevant emissions including carbon and cuts costs,” she enthuses.

Despite Vjosa’s title, hard distinctions between business people and scientists don’t apply here. BASF’s sharkskin crew is a tight-knit team, where everyone feels responsible for the product’s success. “It’s all about the people,” says Dr. Sebastian Hartwig, Head of Functional Films. “People are more important than science to make innovation happen.”

And both have very human motivations for wanting to make aviation more sustainable. For Vjosa, “I love to travel and I don’t believe stopping is a solution. I believe in responsible development.” Sebastian says simply, “I have two kids. They want to grow up on a planet that’s thriving.”

I have two kids. They want to grow up on a planet that’s thriving.

Going forward: reasons to be buoyant

The BASF team believes that further development of sharkskin technology can bring a fuel saving of as much as 3% to the aviation industry. As a result, millions of tonnes of CO2 emissions could be avoided. Together with Lufthansa Technik, the plan is to develop and certify the technology for many additional aircraft types, and make it available to more and more airlines worldwide.

When it comes to climate protection, just like sharks themselves, this is one team that’ll never stop moving.