BASF’s latest TPU technology makes high-performance shoe shank production faster and more cost efficient

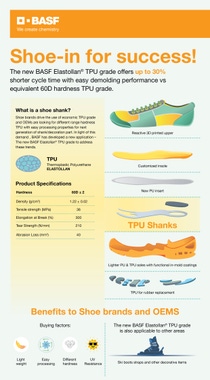

- BASF’s thermoplastic polyurethane (TPU) optimized to provide excellent mechanical properties ideal for shoe shanks

- Advanced material technology empowers greater design freedom for decorative shoe parts

- Energy efficient TPU grade reduces cycle time by up to 30%

Singapore – August 7, 2018 – BASF today introduced an advanced grade of thermoplastic polyurethane (TPU) which can significantly improve production of shoe shanks and decorative shoe parts in high-performance shoes while providing excellent mechanical properties, such as UV resistance. The new Elastollan® TPU grade is also compatible with automation, allowing parts to be easily removed from the mold, and enabling greater design freedom for decorative shoe parts.

“BASF has been providing a broad range of footwear material solutions for years. This new material helps address rising standards and reduce costs for shank production,” said Manfred Pawlowski, Vice President, Consumer, Performance Materials Asia Pacific, BASF. “We are already working closely with shoe brand owners and manufacturers to explore various high-performance footwear applications.”

The new Elastollan grade requires a lower injection temperature, enabling a shorter cycle time, stronger cold flexibility and easy demolding in shoe shank manufacturing. This reduces processing time by up to 30%, depending on the size and thickness of individual parts, which in turn significantly reduces labor costs.

The shank is a part of the supportive structure between the insole and outsole of the shoe. It is typically made with rigid materials to support the foot and stiffen the outsoles for a more stable fit.

Owing to its rigidity, the new grade is also an ideal material solution for sports and leisure products such as ski binders, which connect ski boots to the skis.

About BASF’s Performance Materials division

BASF’s Performance Materials division encompasses the entire materials know-how of BASF regarding innovative, customized plastics under one roof. Globally active in four major industry sectors – transportation, construction, industrial applications and consumer goods – the division has a strong portfolio of products and services combined with a deep understanding of application-oriented system solutions. Key drivers of profitability and growth are our close collaboration with customers and a clear focus on solutions. Strong capabilities in R&D provide the basis to develop innovative products and applications. In 2017, the Performance Materials division achieved global sales of € 7.7 bn. More information online: www.performance-materials.basf.com

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. More than 115,000 employees in the BASF Group work on contributing to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio is organized into five segments: Chemicals, Performance Products, Functional Materials & Solutions, Agricultural Solutions and Oil & Gas. BASF generated sales of €64.5 billion in 2017. BASF shares are traded on the stock exchanges in Frankfurt (BAS), London (BFA) and Zurich (BAS). Further information at: www.basf.com