Change for climate

The ultimate tailwind?

To protect the climate, we have to think hard about the energy we use to power our sites. That’s why, together with our partners, we’re building the world’s biggest subsidy-free offshore wind farm. It will provide low-emission, renewable energy to BASF production sites across Europe – and reduce reliance on fossil fuels considerably. It’s all part of our plan to achieve net-zero emissions by 2050.

The challenge: replacing fossil fuels in production

Switching to electricity is good for climate protection. But, crucially, the electricity needs to be generated from renewable sources in order to be free of CO2 emissions.

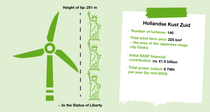

Already completed wind turbines of the wind farm Hollandse Kust Zuid.

The approach: build your own energy source

What’s the best way to guarantee that your electricity sources are supporting the transition to more sustainable energy? Generate your own additional renewable resources. That’s exactly what we’re doing at the Hollandse Kust Zuid wind park with our partners, Vattenfall and Allianz. Located in the North Sea about 18 km off the coast of the Netherlands, it’s set to be the world’s biggest subsidy-free offshore wind park. The first sustainable energy was delivered to the grid in 2022, and when it becomes fully operational in 2024, its 140 turbines will deliver an astonishing 6 terawatt-hours of power per year. That’s roughly equivalent to the average hourly power needed to boil 4 billion electric kettles.

...making sure that BASF products are produced with green power gives me a great sense of purpose

The background: chemistry needs energy

Why do we need so much green energy at BASF? It’s no secret that the chemical industry requires huge amounts of energy to make so many of the products we use every day. To achieve our target of net-zero emissions by 2050, we are vigorously pursuing our ambition to replace conventional fossil energy with new green energy and to electrify our processes. We plan to use our share of the renewable energy from the wind farm to power chemical production at sites across Europe, including the two biggest BASF group sites at Antwerp in Belgium and Ludwigshafen in Germany. It will significantly reduce our reliance on fossil fuels – and, as a result, our emissions.

The team: 100% people-powered

When you talk to the team working on the new wind farm, there’s a huge sense of energy – in every respect. It’s an energy inspired by their contribution to accelerating fossil-free living through the power of the wind. David Brüggen, Joint Venture Manager at BASF Renewable Energy for this wind farm can’t help beaming with pride: “We’re really proud to be part of this transformation, and to actively shape it,” he says. Daniela Herzberg, who works together with the construction and operations team, is bursting with enthusiasm. “Buying renewable power for a large industrial company, making sure that BASF products are produced with green power gives me a great sense of purpose,” she says.

The build: a feat of marine engineering

Building an offshore wind farm isn’t for the faint-hearted. With the turbine blades measuring nearly 100 meters each in length, it’s highly specialised work involving a flotilla of eight ships mounted with cranes and a mini squadron of helicopters. Laying the foundations at Hollandse Kust Zuid alone will be a major engineering and construction feat, with the largest monopile foundation weighing almost 1000 tons and measuring 75 meters in height. That’s why we’re determined to work with the best partners to develop climate-smart ways to power our factories. For this project, we’re partnering with specialists in wind farm construction, Vattenfall.