BASF in Greater China 2023

BASF in Greater China

At a glance

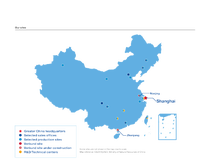

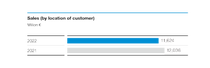

BASF has been a committed partner to Greater China since 1885. With larger production sites in Shanghai, Nanjing, Chongqing, and Zhanjiang (under construction), BASF is a major foreign investor in the country’s chemical industry, and operates the Innovation Campus Shanghai, BASF’s largest R&D site in Asia. BASF posted sales of approximately €11.6 billion1 in 2022 to customers in Greater China and employed 12,115 people as of the end of the year. Greater China is currently BASF’s second largest market after the United States.

BASF currently operates 26 major wholly-owned subsidiaries, 10 major joint ventures, and maintains 23 sales offices in Greater China. BASF’s business in Greater China includes Petrochemicals, Intermediates, Performance Materials, Monomers, Dispersions & Resins, Performance Chemicals, Catalysts, Coatings, Care Chemicals, Nutrition and Health, and Agricultural Solutions.

These solutions are used in almost all areas of daily life such as in houses, cars, food, agriculture, pharmaceuticals, textiles, household goods, electronic equipment, and packaging. Over the past 20 years, BASF has invested more than €9 billion in Greater China (more than €13 billion with partners) to build a locally competitive production, marketing, sales, technical service and innovation network.

1Sales of BASF Group companies in the scope of consolidation, as of December 31, 2022. Sales of joint ventures and associated companies with BASF’s investment of between 20% and 50% in general which are consolidated at equity (e.g., BASF-YPC Company Limited) are not included.

.png)