Paper Coatings

Intelligent Approach To Meet The Demanding Market Requirement In Paper And Board

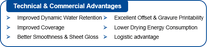

The near-future outlook of the coated paper and board market across Asia is looking gloomy due to difficult global economic and geopolitical developments and trade conflicts. Currently, the coated paper and board mills in China are facing the biggest impact of this challenging economic environment due to market over-supply and ever challenging key monomer raw material price fluctuation. In addition to this, the market requirement has not softened but in fact even more emphasis given towards printability and convertibility.

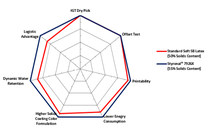

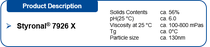

High Solids Binder, Styronal ® 7926 X, Technology-driven Solutions

BASF is highly committed to the growth and the success of the paper industry. Knowing that these benefits are very crucial for the success of our customers, our R&D team has recently developed Styronal® 7926 X, an important step forward in high coating color solids formulation.