Plastics & Rubber

Ultramid® Endure – heat-resistant polyamide for modern engine concepts

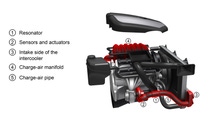

Introduced to the plastics world some time ago, the polyamide specialty Ultramid® Endure has found its place in the automotive sector for innovative engine parts: At the K Fair 2016, BASF will show several powertrain components made of Ultramid® Endure by well-known international tiers 1 for global OEMS. On display will be a resonator, two charge air ducts and an air intake manifold with integrated charge air cooler. They were manufactured either by injection or by blow molding and benefit from the good processing properties and excellent heat-aging resistance of Ultramid® Endure.

Ultramid® Endure is able to withstand continuous use over 3,000 hours at up to 220°C and brief temperature peaks of up to 240°C. It thus extends the application of polyamide into the high temperature range. This makes the plastic the perfect replacement for metal for components used in all parts of the charge air duct, especially those with turbo-charging. Ultramid® Endure offers straightforward processing with a much wider processing window and lower energy consumption than other high-performance plastics or metals – be it by injection-molding or blow-molding.

Ultramid® Endure stays cool – even when it’s hot!

Find out more on Ultramid® Endure here and at our booth at K 2016.

For further technical questions on the product, please contact the Ultraplaste-Infopoint: