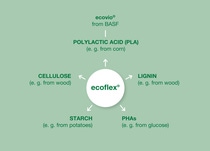

ecoflex® is an ideal blend component for the manufacture of plastics from renewable raw materials, making many final applications possible in the first place. Thus, ecoflex® provides the biobased and compostable BASF polymer ecovio® with special product properties such as flexibility and toughness.

In addition to PLA, other compound partners such as starch can be used to achieve a specific characteristics profile for the final application. A high ecoflex® content is particularly suited for the production of flexible film products in the packaging industry. Mechanical characteristics, such as stiffness or puncture resistance, can be varied and specifically adjusted.