Sustainability

Our solutions: Products for climate protection

BASF products are involved in a large number of climate protection technologies. They enable energy efficiency and climate protection in a variety of sectors, such as building and living, mobility, energy and agriculture.

Examples of our products for climate protection:

.png)

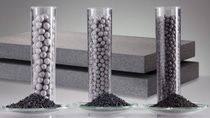

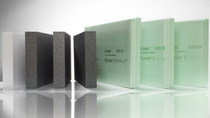

Building and Living

By 2050, nine billion people will live on our planet, three-quarters of them in cities. Growing urbanization will require new concepts in housing and construction. Sustainability is an essential factor for our future. What does our path look like? How can we tackle the new challenges together?

.png)

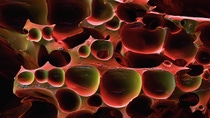

Mobility

Reducing CO2 emissions, meeting recycling targets and improving air quality are industry challenges we all are facing. Limited availability of fossil fuels and climate change call for more efficient cars and lower emissions. “We create chemistry for a sustainable future” – according to this purpose we develop chemistry that drives us from A to B with a cleaner footprint.

.png)

Agriculture

With our connected offer of products, technologies and services, we want to transform agriculture for the better by making a positive impact on the agricultural food system and ultimately on society. We believe that digitalization is at the core of this transformation and has the power to impact billions of people.

.png)

Energy

BASF supports the deployment of wind power as a climate-friendly source of energy. BASF’s innovative solutions are a contributory factor in the more efficient manufacturing and maintenance of rotor blades, bases, towers and gears for wind turbine systems.