Sustainability

Project reciChain - British Columbia Pilot Program

Positioning Canada as a leader in plastics circularity through the reciChainTM program

According to the Government of Canada, every year, Canadians throw away three million tonnes of plastic waste, less than 10 percent of which is recycled. This means that the vast majority of plastic waste produced in Canada ends up in landfills or enters the environment as pollution where it poses a risk to wildlife and their habitat.

To address these challenges, BASF Canada has launched the reciChainTM program, a technology-enabled ecosystem that brings together all the plastic value chain players to enable circularity, tracking and sorting of recycled plastic.

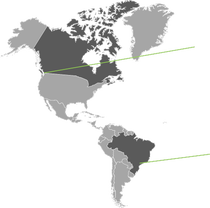

The reciChain concept was created by BASF in Sao Paolo, Brazil and tested with an initial proof-of-concept pilot in 2020 in British Columbia, Canada, that successfully demonstrated circularity by tracking the products lifecycle from pellet to pellet.

Click here to learn more about the BC Pilot

With the support of Alberta Innovates, provincial government corporation responsible for promoting innovation in the province, reciChain is now expanding to Alberta to conduct a subsequent phase of the project which will scale the solution to a semi-commercial phase.

Click here to learn more about the Alberta Innovates funding

reciChain Pilot Consortium Members

Relevant players from the plastics value chain, including BASF, Cascades, Layfield, London Drugs, NOVA Chemicals, Orion Plastics, [Re] Waste, and Waste & Recycling Services from the cities of Calgary and Edmonton, have joined forces in the next phase of reciChain

Revitalizing the Value of Plastics and Improving Circularity within the Supply Chain

A successful implementation of reciChain will support Alberta in achieving impacts such as:

reciChain’s underlining technology components

To extend the lifecycle of plastics, reciChain comprises two technology components:

- A physical tracer that identifies and follows key plastic features throughout the value chain and enables the connection of plastic to a digital twin

- A blockchain marketplace developed by the California-based, Web3 start-up Real Items, which creates and translates the digital twin, providing a secure, auditable transfer-of-ownership and assigning incentives to incent participation and offset cost

News Releases

If you have any questions about this project or if you would like to learn more on how to join the consortium in Alberta please contact:

reciChain is a trademark of BASF, used with permission by BASF Canada Inc. (c) 2022 BASF Canada Inc. All rights reserved. All other trademarks are the property of their respective owners and use of any such trademark does not imply any affiliation with or endorsement by its owner.