BASF launches new 3D printing solutions to make production of complex parts easier and faster

- Versatile solutions from BASF support rapidly-expanding Asia Pacific industrial 3D printing market

- BASF at TCT Asia 2019: February 21-23 at [W4-E50], Shanghai New International Expo Center, Shanghai, China

Shanghai, China – February 21, 2019 – BASF will launch a range of innovative and cross-industry 3D printing solutions at the 2019 TCT Asia exhibition on February 21-23 in Shanghai, China. The new solutions will help make development of complex parts faster and easier, allowing unique designs and making mid-size to serial production more cost-efficient.

“The industrial market for 3D printing in Asia Pacific is growing rapidly, including the automotive, aerospace, medical and dental, and consumer goods industries. These solutions will help our customers accelerate their development cycles, saving time and money while expanding horizons in design,” said Michael Tang, Senior Business Development Manager, BASF 3D Printing Solutions.

BASF will introduce solutions in three areas:

- Powder Bed Fusion: New BASF Ultrasint PA6 LM and Ultrasint PP plastic powders for selective laser sintering (SLS) technology will be unveiled. Ultrasint PA6 LM can deliver high stiffness and thermal stability close to the properties of injection molded PA6 at processing temperatures of 175-185 degrees Celsius. BASF also offers a broad range of plastic powders, such as the Ultrasint PA6 families, Adsint PA12, PA11, & TPU.

- Liquid Formulation Systems: New photopolymers designed for SLA, DLP, and jetting systems will be introduced under the “Ultracur3D” brand. The products are developed for functional components with enhanced mechanical properties, better long-term stability and easier printability and post-processing. Low viscose easy to clean photopolymers for example, dental application will be showcased in partnership with SoonSolid (Xunshi Technology). BASF is also collaborating with the 3D printing solution provider HeyGears on the development of new photopolymers for mass production of industrial components and consumer goods.

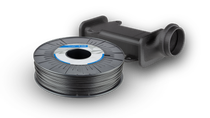

- Additive Extrusion Solutions: In addition to Innofil3D, BASF is introducing a range of Ultrafuse branded filaments. Ultrafuse and Innofil3D reinforced engineering filaments offer good properties, such as high temperature and chemical resistance, stability, and very low moisture absorption – meaning that they also can be used for functional prototyping and even small series production. BASF has partnered with Tianjin Jet-Mate New Material Technology, a local Chinese distributor, to provide better access for customers in China. Printer manufacturers and end-users can also access technical service and application development for functional filament fabrication (FFF) at the BASF 3D Printing Technology Center in Shanghai.

Visit BASF’s booth at TCT 2019 at W4-E50, Shanghai New International Expo Center.

About BASF 3D Printing Solutions

BASF 3D Printing Solutions GmbH, headquartered in Heidelberg, Germany, is a 100% subsidiary of BASF New Business GmbH. It focuses on establishing and expanding the business with materials, system solutions, components and services in the field of 3D printing. BASF 3D Printing Solutions is organized into startup-like structures to serve customers in the dynamic 3D printing market. It cooperates closely with the global research platforms and application technologies of various departments at BASF and with research institutes, universities, startups and industrial partners. Potential customers are primarily companies that intend to use 3D printing for industrial manufacturing. Typical industries include automotive, airspace and consumer goods.

Further information at www.basf-new-business.com.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. The more than 115,000 employees in the BASF Group work on contributing to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio is organized into six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of more than €60 billion in 2017. BASF shares are traded on the stock exchanges in Frankfurt (BAS), London (BFA) and Zurich (BAS). Further information at www.basf.com.