Média

Milestones in BASF’s history

Innovation has been the force guiding BASF history since the company’s foundation in 1865. From indigo to audiotapes to catalysts: insights into BASF’s past and present.

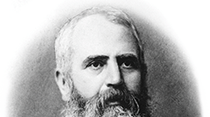

1865

Friedrich Engelhorn, a goldsmith and entrepreneur, founds the joint-stock corporation “Badische Anilin- & Sodafabrik” (BASF) in Mannheim in 1865. He has big plans from the word go: BASF should not only produce dyes but also the raw materials and auxiliaries as well as the precursors and intermediates required. BASF has retained soda, aniline and dyes in its portfolio to this day – while continuously adding to its product range along the way.

1897

A broken thermometer sets the scene for a breakthrough in indigo research. In this example of serendipity at work, BASF scientists discover that mercury is an excellent catalyst in the manufacture of phthalic acid, a key precursor in the synthetic production of indigo. Economic industrial production of the precious blue dye seems a viable option at long last. Seventeen years of research later, it is finally ready for sale as “Indigo rein BASF” (English: Indigo Pure BASF). The synthetic indigo is sold worldwide, especially in China, where blue jackets dyed with indigo are traditional clothing and BASF has been active since 1885. Later, in the 1960s, indigo blue denim jeans are adopted by an entire generation and have become a basic wardrobe essential for many people all over the world today.

1913

By the turn of the century, reserves of atmospherically fixed nitrogen – used as a crop fertilizer in the form of sodium nitrate – are running out. New sources of nitrogen are badly needed. After five years of research and development at BASF, Carl Bosch, building on a process by the Karlsruhe-based chemist Fritz Haber, succeeds in converting atmospheric nitrogen on an industrial scale and manufacturing synthetic ammonia, which is used in turn to produce nitrogen fertilizers. The downside of the method shows itself in the First World War, when ammonia is converted into nitric acid and supplied to the explosives industry. Ammonia synthesis was developed to provide for the nutrition of billions of people – and continues to do so today.

1936

In 1936, the London Philharmonic Orchestra has a guest appearance at the BASF Feierabendhaus in Ludwigshafen. Their visit is recorded for posterity in the world’s first live recording of a concert on audiotape. Tapes for the recording of sound are originally intended for dictation purposes. However, the concert demonstrates the possibilities of BASF’s new magnetic tape. Radio stations are among the first to use the tapes. In 1969, the Beatles record their unreleased “Get Back Sessions”, one of the band’s last projects, on a BASF tape. In 1997, BASF sells its global magnetic tape business to the South Korean KOHAP Group.

1951

Styropor is one of the classics of plastics and a lightweight among foams. It has been produced since 1951 and is composed of 98% air. Until now it is a byword for efficient home insulation and safe packaging. In 1962, the Mona Lisa, for example, is sent off on her travels wrapped in Styropor. In 1964, Kuwait Harbor is the scene of a rescue operation with a difference: a sunken livestock carrier is raised with the aid of Styropor beads pumped into the ship’s interior. Unfortunately, a patent filing for this unusual salvage method goes up in smoke when it transpires that Walt Disney told the tale of a similar salvage operation back in 1949 – the protagonist being Donald Duck, who used ping pong balls to raise a sunken yacht. In patent law terms, this constitutes a prior description that well and truly scuttled any hope of patenting the Styropor operation in its entirety.

1974

Although BASF was actually founded in 1865 as a waste recycler – producing synthetic dyes from what had been an undesirable waste product, namely coal tar – it also generates pollutants. BASF’s first steps to protect water, soil and air are to introduce the removal of arsenic from fumes in 1903 and wastewater discoloring in 1905. In response to increasing environmental awareness and stricter regulations, BASF steps up its environmental protection efforts from the 1960s onward. One important milestone is the commissioning of the new water sewage treatment plant at the Ludwigshafen site in 1974. It is Europe’s largest mechanical-biological sewage plant at the time. Modernized continually ever since, it is the main element in a sophisticated wastewater concept that has evolved over decades with separate sewer lines for cooling water and wastewater.

2013

There are an estimated one billion cars on the world’s roads, and that has an impact on the environment. Incomplete combustion and minimal contaminant levels in fuel can produce harmful car exhaust fumes. After Engelhard Corporation, acquired by BASF in 2006, achieved a breakthrough in 1976 with the first three-way catalyst, BASF researchers went on to find the key to an even cleaner solution in 2013 by developing the first FWC™ four-way conversion catalyst for gasoline engines. This new technology filtrates and removes the most important groups of harmful emissions (hydrocarbons, carbon monoxide and nitrogen oxides) and particulate matter from engine exhaust using just one single component.

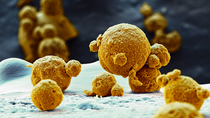

2015

Originally established in Mannheim, BASF now calls the world its home with a network of about 380 production sites and research teams at a total of 70 research sites. Innovation has always been a powerful driver of growth. Currently BASF is focusing on growth fields such as wind energy, water solutions and batteries for mobility (microscopic image).