Products

Industrial Coatings

Industrial evolution

From heavy equipment to satellites, the applications for industrial coatings are highly diverse and constantly evolving. Yet as varied as they are, they all share one factor: demanding technical requirements combined with pressure to reduce total formulation costs.

Based on vast experience in many of the most challenging segments, including aerospace and marine coatings, BASF Performance and Formulation Additives has developed solutions that ensure maximum protection and durability under stress, as well as qualities like haptics or resistance to weathering, color fading and dirt pickup. At the same time, our high-performance additives can enable coatings with specialized properties such as adhesion with multiple materials or thinner and fewer coating layers. In addition, we support you in meeting regulatory standards with innovative concepts and products. We enable water-based and low-VOC formulations, as well as industrial coatings that contain hazard label-free materials.

Because the category of industrial coatings encompasses so many different applications, we are keenly focused on the individual demands of each industry. For BASF, scientific research in specialized industrial coatings is an investment that pays off in win-win partnerships. This means regardless of which materials your coatings must adhere to and which types of stress they must withstand, you can count on our experts to cooperate with you and develop solutions for your needs.

Marine coatings

With their anti-corrosive or anti-fouling properties, marine coatings are designed for all kinds of vessels, including commercial and cargo ships. Coatings for offshore oil rigs and equipment are described under “Protective and maintenance coatings”.

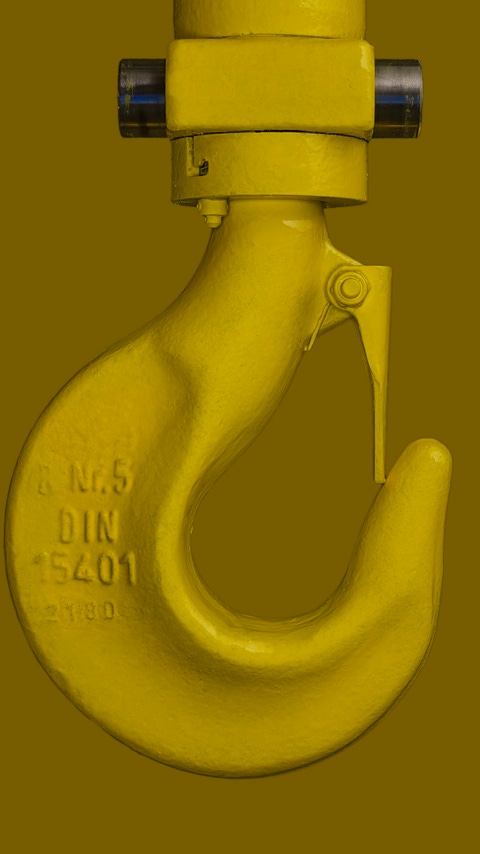

Protective and maintenance coatings

Also known as heavy-duty or high-performance coatings, protective and maintenance coatings are applied on steel structures, steel bridges, off-shore oil rigs and equipment, chemical and petroleum plants, piping and other structures requiring protection against corrosion and/or high resistance to wear and tear. These coatings generally require much thicker film (i.e. 3-4 mm) than architectural and decorative coatings. BASF's resin technology includes polyurethane, polyester and epoxy. Typical applications include heat-resistant coatings for pipes and flares, heavy-duty floor paint for factories, warehouses and airport hangars and high-performance coatings for oil-rig towers, bridges, plant and related equipment.

Can coatings

These coatings are applied on the inside of cans to ensure protection i.e. to prevent the metal from reacting with the contents of the can, and on the outside for decorative purposes.

Coil coatings

Pre-finish metal coatings, or coil coatings, are applied on continuous metal sheets, strips and coils, which are subsequently sold to OEMs (Original Equipment Manufacturers). Applications range from gutters and household appliances to automobile and electrical components.

Brochures