The new source

Bright sunshine, a cloudless sky: beautifully sunny weather draws millions of holidaymakers to the island of Cyprus every year. Nevertheless, the hot, dry climate brings difficulties of its own. Water is a scarce commodity in Cyprus and the country is seeking sustainable solutions to address the problem.

Water as a scarce resource

Cyprus experienced months of drought in 2008. Existing water reserves were insufficient to meet drinking water supply needs, prompting the government to order water rationing. Cypriots were given access to running water for just 12 hours every other day and drinking water had to be imported from Greece.

Water scarcity in Cyprus has a variety of causes. According to the Water Development Department, the Cypriot Water Development Ministry, precipitation levels have plummeted since the 1970s. Natural recovery of water resources therefore looks highly unlikely. Intensive agriculture and the growth of tourism are other factors involved in causing the country’s water depletion problem. Deeper and deeper wells are being drilled to tap into groundwater sources. In conjunction with major lowering of the water table, this has resulted in some areas in causing salt water from the sea to enter subterranean aquifers.

Sea water desalination to maintain the water supply

According to Yianna Economidou, chief engineer of the Water Development Department, responsible handling of water resources is crucial: “We are committed to sustainable development of our water resources in combination with requirements management.” What it actually means is that farmers are allocated water quotas and have to pay a fine if they exceed them. The Water Development Department also provides recycled water from local authority water treatment plants for irrigation. However, these measures are not enough to cover the aggregate water requirement for agriculture, tourism and private households.

Economidou says desalination of sea water is the only way to maintain the island’s water supply regardless of climatic conditions. Cyprus has experience in desalinating sea water going back as far as 1997. “That’s when the first desalination plant was built,” Economidou says.

“Desalination capacities have been expanded continuously and now we are able to meet 100% of our drinking water requirement for local authorities and tourism from sea water desalination plants.”

Yianna Economidou, chief engineer, Water Development Department

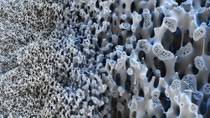

Ultrafiltration membranes play an important role in desalination. Filters with extremely small pores retain suspended particles, and hazardous microorganisms such as viruses and bacteria are effectively and reliably separated from the water as well. This helps turn waste water into drinking water. The membranes operate similarly to conventional filters. While water molecules penetrate through pores just a few nanometers in size, suspended matter such as sand, silt, algae and even disease-causing organisms cannot pass this barrier. The BASF subsidiary inge® headquartered in Greifenberg, Bavaria manufactures ultrafiltration membranes for a variety of water treatment applications. “The starting material is a high-performance polymer,” Chairman of the Board Bruno Steis reveals. “We use it to produce extremely stable UF membranes by a method of our own design.”

The membrane technology is suitable for use in a preliminary stage of reverse osmosis. With this type of desalination, salt water is forced through a reverse osmosis membrane at high pressure. Water passes through the membrane while the salt is left behind.

The Bavarian company supplies upstream filter stages for reverse osmosis which are used to pretreat the salt water in order to optimize the actual reverse osmosis process. As energy consumption is significantly lower with a combination of ultrafiltration and reverse osmosis, this method is growing in popularity.

Professor Claudia Staudt, a BASF membrane expert, is working with her Ludwigshafen team to improve the membrane material: “The aim is to develop membranes that produce clean drinking water while using up as little energy as possible.” This can be achieved for instance with a surface material designed so that organic or inorganic material from the water does not adhere to it. The less material that clogs the filter pores, the longer a filter can operate without needing to be cleaned or replaced, and the longer the plants can stay in operation. All this has benefits in terms of cost and environmental impact.