Innovation

Battery materials

Electric cars have been painted as part of the solution to reduce emissions globally, but many people remain wary about their practicality. What if our innovations in battery materials help to double the real driving range of a typical midsize car to 600 km, on a single charge? And what if we could reduce the charging time to 15 minutes by 2025?

Our innovations in battery materials will help to make e-mobility fit for everyday use. Wouldn't it be great to recharge your e-car in 15 minutes and continue a 600 km drive by 2025? And wouldn't it be nice to recharge yourself from daily stress in those 15 minutes?

We asked the same questions to independent filmmakers. This is how they would recharge themselves in 15 minutes:

Driving 600 km on a single charge

By 2025, our innovations in battery materials aim to double the real driving range of midsize cars from 300 to 600 km on a single charge — regardless of whether the air conditioning is running or the music is turned up at full blast.

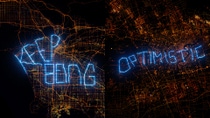

Thanks to our innovative battery materials, we are optimistic about the future of e-mobility. This is symbolized in the picture below. In a combined 600 km journey in Los Angeles and Shanghai, a message is "written" in the streets by GPS: "keep being optimistic".

This is how we're shaping the future of e-mobility

Cathode active materials are central to the performance, affordability, reliability and sustainability of advanced electric vehicle batteries. Our researchers use a comprehensive "toolbox" of different methods to influence the properties of the materials: from the composition of the metals, different particle sizes and distributions, to the adjustment of porosity and surface properties.

Sustainability

Our ambition is to create a sustainable battery materials value chain for electric vehicles. Electromobility is one of the key solutions to merge the global desire for individual mobility and the need to significantly reduce local emissions, especially in combination with renewable energy. As a global leading supplier of battery materials for lithium-ion batteries, we aim to contribute to sustainable battery materials value chain and make e-mobility a practical reality for everyone.

Digitalization accelerates research

We generate more than 100 million data points every day when we test our material in small test batteries. Machine learning and our supercomputer Quriosity help predict and analyze material properties, accelerating our research.

Where will our battery materials take you?

We believe the development of advanced emission control technologies and the increasing demand for electric powered cars will help reduce emissions and increase air quality on a global scale. Fewer emissions will make our world a better place to live by reducing the impact of air pollution in inner cities and creating a positive effect on the health of the population.

For latest news, please also follow our channel on LinkedIn.

.jpg)