Factbook

Battery Materials

BASF’s Battery Materials division is a global leader in advanced cathode active materials (CAM) for lithium-ion batteries. We empower the world’s leading cell manufacturers and OEM platforms with high-performance solutions tailored to their needs. In addition, our portfolio includes precursors, base metals sourcing and management as well as battery recycling solutions. By leveraging our industry-leading R&D platform and passion for innovation, we develop unique, proprietary solutions that drive customer success and support the transition towards electromobility. Through our global production and R&D footprint across key regions, we ensure a reliable supply of high-quality materials and localized support for our partners, allowing us to better serve our customers worldwide.

Sales by direct customer industry 2024

Portfolio

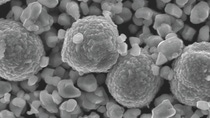

Cathode active materials (CAM)

Cathode active materials are the heart of a lithium-ion battery. Within the electrified powertrain, they provide the greatest level of differentiation and comprise the largest material value.

Our innovative and proprietary know-how allows for customization of the optimal CAM dedicated for specific application segments and customer needs. Our broad product portfolio includes

- Materials with high capacity or fast-charging capabilities

- Technically high-performing materials for high-end applications

- Materials to maximize battery lifetime

- Materials with a customized balance of energy, power, lifetime and costs

Thanks to our broad portfolio, we offer materials suitable for all battery cell applications, including light-duty vehicles, heavy-duty vehicles, stationary energy storage, consumer electronics, e-bikes or e-scooters, medical devices or power tools as well as aerospace, aviation and marine applications.

Battery recycling

Battery recycling allows valuable materials contained in end-of-life batteries and production scrap to be recovered and reintegrated into the production cycle. Recycling reduces the dependency on primary mining resources as well as emission of greenhouse gases, while establishing a local supply of key raw materials.

Based on our extensive knowledge of the electric vehicle industry and our unparalleled expertise in the chemical industry, we have developed comprehensive solutions for battery recycling. We are thus able to cover all steps along the entire battery recycling value chain, from logistics to discharging and dismantling, as well as black mass production and refining, leveraging our strong partner network.

Metals management

Raw material security and metal risk management solutions are essential to enable a successful battery business. BASF provides metal management services to customers to manage their risks more effectively. We offer a full range of services, including ensuring security of supply through global sourcing and recycling footprints, effective price risk management, liquidity management through trading, global end-to-end optimization of metal flow, supply and inventory management or fixed and index-based pricing mechanisms and forward hedges. We have also established a responsible sourcing management framework to enable low CO2 footprints and a strong ESG performance.

Market position and main competitors

The Battery Materials division holds one of the top five market positions in all strategic business areas in which it operates.

The main competitors (alphabetical order) include Easpring, EcoPro BM, Huayou, LG Chem, Posco Future M, Ronbay and Umicore.

Focus of research and development

Our innovation strategy for battery materials focuses on three key areas:

- We develop high-performance CAM for lithium-ion battery technologies. This enables our customers to optimize their battery cells in terms of cost, stability, sustainability and safety.

- We create advanced solutions for the recycling of lithium-ion batteries. In doing so, we not only enhance sustainability, but also improve long-term raw material security.

- We explore new materials and production technologies to ensure our future readiness. This includes researching CAM for solid-state batteries, sodium-ion batteries, and innovative materials that minimize the use of costly and scarce metals such as nickel and cobalt.

Through our global R&D setup, we collaborate with customers across different regions, maintain proximity to production plants and foster partnerships with leading academic and technological institutions worldwide.

Acquisitions/JVs/investments

From 2022 onward

| Product group | Description | Year |

| Battery materials | CAM capacity expansion for the joint venture BASF Shanshan in Chansha, China | 2023 |

| PCAM manufacturing plant in Harjavalta, Finland | – 1 | |

| CAM manufacturing plant in Schwarzheide, Germany | 2023 | |

| Battery recycling prototype plant in Schwarzheide, Germany | 2024 | |

| CAM capacity expansion for the joint venture BASF TODA in Onoda, Japan | 2024 | |

| Black mass recycling plant in Schwarzheide, Germany | 2024 |

1 The startup date of the plant depends on the outcome of a potential investment decision by BASF, following the granted permit.

Innovation

Lithium manganese oxide (LMO) and nickel cobalt manganese (NCM) blends

BASF has developed innovative LMO/NCM blends that combine the best features of both materials to enhance battery performance. LMO is known for its cost-effectiveness and ease of manufacturing, while NCM offers high energy density and excellent cycle life. By mixing these materials, BASF achieves a unique balance of cost and performance, making such blends suitable for low-cost automotive applications. The LMO/NCM blends provide fast charging capabilities, high recycling potential, and improved low-temperature performance compared to traditional LFP (lithium iron phosphate) and LMFP (lithium manganese iron phosphate) batteries. These blends are designed to be a drop-in solution for existing battery manufacturing processes, allowing for seamless integration and flexibility in meeting the diverse demands of the electric vehicle market. BASF is currently collaborating with various partners in the battery value chain to bring LMO/NCM material blends to the market in the coming years.