Media

Water-based inks and adhesives as a valuable contribution to sustainability in flexible packaging

- Water-based Joncryl® and Epotal® offer less environmental impact at similar costs and performance compared to solvent-based technologies

- Eco-Efficiency Analysis (EEA) proves a reduced carbon footprint for water-based inks and adhesives of about 15%

- BASF presents water-based technologies for printing and converting at Interpack 2017

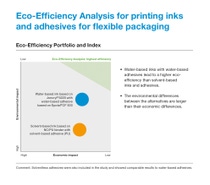

BASF’s water-based resins for inks and adhesives in flexible packaging are an economically compatible and environmentally friendly alternative to solvent-based technologies. This is the result of a recently completed Eco-Efficiency Analysis conducted by BASF and based on previous Eco-Efficiency Analysis for water-based printing inks for flexible packaging in 2009 as well as data from a recent EEA for adhesives in 2016. The study considers a broad range of environmental categories of the final product and its raw materials (cradle-to-grave) ranging from climate change and resource depletion to water over-fertilization.

The BASF Eco-Efficiency methodology was validated by NSF International while the results of the study were critically reviewed by DEKRA as an independent third party.

The outcome of the EEA demonstrates that water-based inks and adhesives lead to a higher eco-efficiency than solvent-based inks and adhesives. The main driver of environmental differences among the alternatives is the production of inks and solvents.

Improved health and safety while reducing the carbon footprint

The analysis showed that solvent-based inks and adhesives perform worse in all impact categories which is mainly due to the environmental impact related to the production of the organic solvent for use in the printing process, ink raw materials and adhesive production. Furthermore, the EEA demonstrates that a shift from solvent-based inks and adhesives to water-based technologies will allow a reduction of greenhouse gas emissions (CO2 equivalents) of up to 15 %. This reduction of the carbon footprint is of increasing importance for brand owners and converters.

Water-based technologies also have a positive impact on health and working place safety. “As water-based inks and adhesives contain neither organic solvents nor aromatic isocyanates, production risks are reduced to a minimum”, says Ulf Neidlein, Vice President Business Management Resins & Additives Europe. “They offer a great improvement in industrial safety and are therefore an important step towards more sustainable and safer solutions for flexible food packaging.”

Reduced overall costs

The results of the EEA reveal that solvent-based inks and adhesives have the highest overall costs, due to a high volume of required solvents. “Conversion to water-based systems will result in reduced investment and maintenance costs since solvent incineration or recovery will not be required anymore”, adds Jürgen Pfister, Vice President Dispersions for Adhesives & Fiber Bonding Europe. “Furthermore, the overall production time for our customers can be significantly reduced with water-based adhesives as converters can laminate and deliver within one day.”

BASF presents water-based technologies for flexible packaging

An industrial printed and converted flexible packaging exclusively produced with water-based technologies and therefore benefiting from the advantages proven in the EEA will be exhibited at Interpack 2017 in Düsseldorf from May 4-10 at booth 43, hall 10. The pizza tray packaging is a joint effort of BASF with its value chain partners AMB and Sun Chemical produced with water-based adhesives from the Epotal® FLX range and printed with water-based inks based on the Joncryl® FLX product range.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. The approximately 114,000 employees in the BASF Group work on contributing to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio is organized into five segments: Chemicals, Performance Products, Functional Materials & Solutions, Agricultural Solutions and Oil & Gas. BASF generated sales of about €58 billion in 2016. BASF shares are traded on the stock exchanges in Frankfurt (BAS), London (BFA) and Zurich (BAS). Further information at www.basf.com.

About BASF‘s Dispersions & Pigments division

The Dispersions & Pigments division of BASF develops, produces and markets a range of high-quality pigments, resins, additives and polymer dispersions worldwide. These raw materials are used in formulations for coatings and paints, printing and packaging products, construction chemicals, adhesives, fiber bondings, plastics, paper as well as for electronic applications such as displays. With its comprehensive product portfolio and its extensive knowledge of the industry, the Dispersions & Pigments division offers its customers innovative and sustainable solutions and helps them advance their formulations. For further information about the Dispersions & Pigments division, please visit www.dispersions-pigments.basf.com.

P-17-210