Media

Ultradur® RX – more clarity for radar sensors

- PBT meets the high requirements of sensors for automated driving

- Ultradur® RX absorbs and reduces signal noise, thus increasing the safety in road traffic

- Versatile product grades are now available

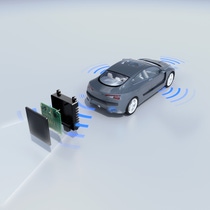

The development of new technologies for the automotive industry focuses on comfort and the safety of passengers. Chemistry has already made a decisive contribution to this and will also play an important role in future mobility challenges. In addition to electromobility, automated driving is a crucial building block for the mobility of tomorrow. Closely linked to this development is the increased use of sensors.

High demand on sensors for self-driving cars

With Ultradur® RX, BASF has now developed a modified polybutylene terephthalate (PBT) specifically for radar sensor applications in vehicles. Thanks to its good resistance against media such as splash water, oils or salt, Ultradur® offers an exceptional protection for sensor housings. In addition, the new material shields the sensitive electronics in the housings against disturbing electromagnetic waves from other vehicles.

"The different grades of the new Ultradur® RX series are products designed for absorption and reduction of interference radiation in the range of 76 to 81 GHz. They offer a high level of protection of the sensitive electronics," explains Dr. Erik Gubbels, R&D Ultradur® expert in the Performance Materials division at BASF. "This dielectrically optimized material fulfills the high standards for sensor components and is suitable for the use as a rear housing cover or behind the printed circuit board of a radar sensor, for example."

Absorption and reflection of interference radiation

With increasing electromagnetic interference issues in road traffic, it is crucial that for optimal sensor functioning this noise is absorbed and therefore reduced. That makes Ultradur® for the perfect choice. By suppressing disturbing radar radiation, a better assignment of the received signals is possible, which at the same time means an improvement in safety. As a functionalized plastic, Ultradur® RX is an excellent alternative to metal housings, thus contributing to weight savings and higher vehicle efficiency.

Since the absorption properties depend on geometric conditions, the suitable material must be selected for each application - the new Ultradur® RX portfolio offers an ideal solution for any circumstance and is now commercially available.

Receive up-to-date news releases from BASF via push notification on your smartphone. Register for our news service at basf.com/pushnewsbasf.com/pushnews.

About BASF’s Performance Materials division

BASF’s Performance Materials division encompasses the entire materials’ know-how of BASF regarding innovative, customized plastics under one roof. Globally active in four major industry sectors – transportation, construction, industrial applications and consumer goods – the division has a strong portfolio of products and services combined with deep understanding of application-oriented system solutions. Key drivers of profitability and growth are our close collaboration with customers and a clear focus on solutions. Strong capabilities in R&D provide the basis to develop innovative products and applications. In 2019, the Performance Materials division achieved global sales of €6.06 bn. More information online: www.plastics.basf.com.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. More than 117,000 employees in the BASF Group work on contributing to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio is organized into six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of €59 billion in 2019. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the U.S. Further information at www.basf.com.

P-20-366