BASF’s Thermoplastic Polyurethane (TPU) chain of custody certified

- TPU plants in Mainland China and Taiwan received ISCC PLUS

- Helps customers meet sustainability goals and advance in their green journey

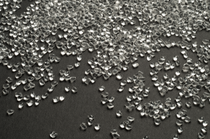

Shanghai, China – June 30, 2023 – BASF continues to demonstrate its commitment to helping customers meet sustainability goals and advance in their green journey with the rollout of more site certifications that verify its chain of custody - BASF’s Thermoplastic Polyurethane (TPU) plants in Mainland China and Taiwan have received the International Sustainability and Carbon Certification (ISCC PLUS).

The certification enables BASF to offer sustainable grades for its TPU products. The certification validates claims that BASF’s TPU products with a reduced Product Carbon Footprint (PCF) produced out of its plants in Mainland China and Taiwan are made with a drop-in solution of renewable feedstock using a mass balance approach - while providing the same product performance as the fossil-based product.

“A certified chain of custody is the only guarantee for non-fossil recycled and renewable feedstock. The ISCC PLUS certification covers the entire value chain and ensures that the indicated amount of fossil feedstock is replaced with renewable feedstock. Hence it is of a strategic focus on our green journey to support customers in meeting their sustainability targets,” said Andy Postlethwaite, Senior Vice President, Performance Materials Asia Pacific, BASF.

TPU is typically applied in footwear, sports and leisure products.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. More than 111,000 employees in the BASF Group contribute to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio comprises six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of €87.3 billion in 2022. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the United States. Further information at www.basf.com.

About Performance Materials

BASF’s Performance Materials division is at the forefront of the much-needed sustainability transformation in plastics. Our products are co-created with customers around the globe to bring innovations to four major industry sectors – transportation, consumer goods, industrial applications, and construction. Our R&D focuses on all stages of the plastics journey: Make, Use and Recycle. The MAKE phase is about improving how plastics are made, from product design to the choice of raw materials and the manufacturing process itself. The USE phase enhances plastics’ strengths such as light weight, robustness, and thermal resistance. At the end of the product lifecycle, the RECYCLE phase looks at how to close the loop to achieve a circular economy. In 2022, the Performance Materials division achieved global sales of €8.5 billion. Join #ourplasticsjourney at: www.plastics.basf.com

-BASF-Thermoplastic-Polyurethane-TPU.pdf/jcr:content.jpg)