Produkty

Ultrason® (PSU, PESU, PPSU) – The Specialty Plastic for High-quality Parts

Our Ultrason® grades are materials especially designed for applications that require high heat resistance ‒ they always keep stiffness and dimensional stability even when used at very high temperatures. Their wide spectrum of properties allows them to be molded into high-quality engineering parts and highly stressed mass-produced articles.

Ultrason® E, S, P (PESU, PSU, PPSU)

The Ultrason® resins are amorphous thermoplastics derived from polyethersulfone (PESU), polysulfone (PSU) and polyphenylsulfone (PPSU) and offer very high resistance to heat. Their wide spectrum of beneficial properties allows them to be molded into high-quality engineering parts and high-load mass-produced articles. They can be processed by almost all the techniques adopted for thermoplastics.

Ultrason® can be successfully used for applications in which other plastics, e. g. polyamide, polycarbonate, polyoxymethylene and polyalkylene terephthalates, fail to meet the requirements. By virtue of their extraordinary versatility, Ultrason® resins can substitute thermosets, metals and ceramics.

The extraordinary property profile of Ultrason®

- Very high long-term service temperature

- Excellent transparency

- High stiffness, good dimensional stability and mechanical strength even at high temperatures

- Very favorable behavior in case of exposure to fire

- Excellent hydrolysis resistance

- Favorable dielectric properties

Ultrason® at the K Fair 2019

Andreas Anetseder, inventor of the Krempel, and Georg Grässel from BASF show at the K Fair how playfulness, design and functionality can be combined with engineering plastics: with the foldable trivet Krempel® from oha-design. The company is now using the high-performance plastic Ultrason® P to produce the extremely loadable plastic strips.

Roll it up! Foldable trivet Krempel® from oha-design now also made of Ultrason® P

A simple yet technically sophisticated household item shows how playfulness, design and functionality can be combined with engineering plastics: the foldable trivet Krempel® from oha-design, Germany. This kitchen helper consists of four flexible, flat plastic strips, which are connected to each other with rivet joints. By pushing or pulling the original flat shape, it can be turned inside out or bent in a variety of ways to create stable, three-dimensional shapes like a circle, pillow or fish. The company oha-design is now using the high-performance plastic Ultrason® P to produce the extremely loadable plastic strips. The polyphenylsulfone (PPSU) ensures that the trivet always retains its shape, is flame retardant and can be easily cleaned in a dishwasher.

Andreas Anetseder, owner of oha-Design and inventor of the Krempel®:

“For a year and a half I puzzled over it, experimented with wood and metal and finally implemented the Krempel® in plastic. By the time it was ready for serial production, I had learned a lot about plastics – and also that, even with such an apparently simple design object, everything has to fit together perfectly: the properties and thickness of the materials, the diameter of the disks and rivets as well as the exact processing in injection molding. Only then can the trivet be turned into different shapes in this astonishing way, as if by magic.” The name, too, contributed to the success of the design object, which was awarded the German Design Award in 2017: “There’s always room for a bit of irony. The name Krempel is not only derived from the German verb ‘krempeln’ meaning ‘to fold’ or 'to roll something up', but also from the noun ‘Krempel’, meaning useless household items or stuff. Hopefully that’s not the case for the Krempel® trivet, even if you don't just use it in the kitchen, but simply fool around with it.”

For more information, please go to www.oha-design.de

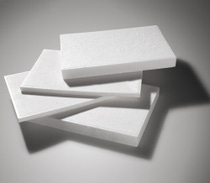

The world's first particle foam based on polyethersulfone

- Prototypes with unique combination of properties: lightweight, stiff and strong, highly temperature resistant, intrinsically flame retardant

- Suitable for complex-shaped components in cars, airplanes and trains

After two years of intensive research, BASF is now able to present prototypes of the world's first particle foam based on polyethersulfone (PESU).

The foam is characterized by its unique combination of properties:

- high-temperature resistance

- inherent flame retardancy

- extremely light while stiff and strong

It is therefore particularly well suited for complex-shaped components in cars, airplanes and trains, which require excellent mechanics together with the ability to withstand high operating temperatures or meet stringent flame-retardant requirements. The expandable PESU granulate is pre-foamed into beads with low densities between 40 and 120 g/L and can be processed into molded parts with complex 3D geometries using technologies available on the market.

Discover our Product Range

Tailor-made Solutions

Tailor-made for individual needs: We support our customers in developing application-oriented solutions.

Our Service Package

We offer our customers a comprehensive range of services with leading technologies and products. Find the service that matches your needs!

Innovative Products

In addition to Ultrason® we offer further innovative materials. These might also be interesting for you.