Dispersions, Resins and Additives

LUX Furniture Composites

A lightweight bio-composite material made in cooperation between Maria Yee Inc. and BASF

What is LUX™?

Based on advanced lightweighting technology designed for the European auto industry, LUX™ is an entirely new composite material created to bring lightweight strength to home furnishings. LUX features a revolutionary use of natural fiber that enables innovative and sustainable furniture design. Maria Yee, Inc. is proud to introduce LUX to the furniture industry.

Where is LUX currently being used?

Natural fiber composites like LUX with natural bast fibers and BASF resin technology have been used in automotive applications by BMW, Mercedes, Volkswagen, Opel/GM and the Fiat Group. Some examples include doorpanels in BMWs or Mercedes roof frames. These lightweight materials help to improve fuel effciency through significant weight reduction helping car manufacturers meet new regulatory fuel consumption standards. At the same time, LUX meets the demand for increased renewable material choices in this industry.

How does LUX compare to MDF?

Very low emissions

The BASF binder used in LUX boards creates a material with a very low volatile organic compound (VOC) emission profile. Binders used in MDF boards often contain phenol formaldehyde (PF), urea formaldehyde (UF) or isocyanate based binders which can result in harmful exposure during manufacturing and usage. LUX is free of any potentially harmful emissions.

Sustainable material content

Unlike MDF boards, the sustainable natural fibers used in LUX boards are “bast” type fibers like kenaf or jute. Harvesting these fibers does not contribute to deforestation, nor does it compete with the food supply chain. These fast growing fiber sources make up approximately 70% of the reinforcement fibers in the LUX board.

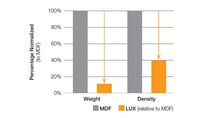

Weight reduction

LUX is much thinner and lighter than MDF boards at a comparable specifc modulus of elasticity (MOE). Through intelligent design, the performance of an MDF board can be achieved while contributing to a significant weight reduction. A LUX board is approximately 60% less dense, which can result in up to a 90% weight reduction when compared to an MDF board.

Resistance to heat

LUX boards are comparable in heat resistance to MDF boards. They have been tested up to 275°F with hot platen steel.

Resistance to environmental changes

LUX boards maintain relatively uniform expansion in all directions with an overall warp of less than 1% approximately, about 10 times more resistant than MDF boards.

Resistance against stains and mold

LUX boards are sealed with a film on the surface that acts as a water tight barrier against mold growth and stains.

Appearance and feel

LUX boards are available in multiple colors and always provide the feel and look of natural fibers.

| Material | Average Volume Change (Overall Warp) % |

|

| LUX | -1.10% | |

| MDF | 11.60% |