Who we are

Product Carbon Footprint of Raw Materials

We see sustainability as an integral part of our strategy as well as our targets, steering processes and business models to enable the green transformation of our customers.

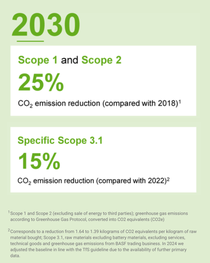

In order to deliver the chemical products that support our customers on this journey, we are taking a comprehensive approach to emissions reduction. While reducing Scope 1 and 2 emissions through innovative and cost-effective measures is important, our commitment extends across the entire value chain. That’s why we have also set a specific 3.1 target that encompasses everything from the raw materials we procure to our factory gates:

Procuring low-PCF raw materials contributes twofold to our strategic ambition: It enables us to offer products with a lower carbon footprint to our customers. And it helps us achieve our emission reduction targets as a company. Only in close collaboration with our suppliers we will be able to achieve these goals.

.png)

Why the Carbon Footprint of Raw Materials matters

On average, around 70% of the carbon footprint of our products originates from our purchased raw materials. It arises from the upstream supply chain, particularly from the extraction, production, and transportation of raw materials:

Extraction emissions arise during the extraction of natural resources from processes like mining or drilling.

Processing emissions occur during the processing of extracted raw materials, which may involve refining, smelting, or chemical transformation.

Transport emissions are associated with the logistics involved in moving raw materials from extraction sites to processing facilities.

%20(1).png)

In order to calculate the PCF of our 45,000 sales products, BASF has pioneered PCF data collection and built an industry-leading system enabling us to provide PCFs calculated with a TÜV-certified digital solution.

%20(2).png)

%20(3).png)