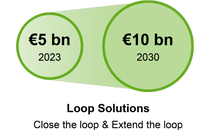

We aim to reach €10 billion sales from

Loop Solutions for our customers by 2030

Sustainability

Our approach to a Circular Economy

Another key contribution in our development, innovation and production work is thinking in terms of the circular economy. Circular economy means decoupling growth from resource consumption. BASF is driving circular economy by making the most of the limited resources of our planet: We keep them in use for as long as possible, minimize waste and create value with renewable resources.

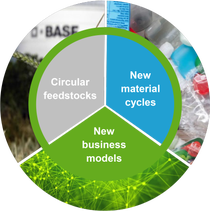

Climate change, loss of biodiversity and environmental pollution pose significant threats to humanity's livelihoods. The current overexploitation of natural resources is one of the main causes of these problems. At BASF, we are aiming to transition to a circular economy by focusing on using increased amounts of circular feedstocks (both recycled and renewable), designing new material cycles and establishing new business models.

New business models

We enter new markets, create smart digital solutions and offer new services which allow a decoupling of growth from resource consumption.

New material cycles

We design materials for circularity, develop solutions which improve or enable recycling, enable higher durability and prolonged lifetime/use phase of products, and establish product-specific recycling loops.

Circular feedstocks

We will increase the volume of renewable and recycled feedstocks from sustainable sources, also via the certified mass balance approach.

Loop Solutions

Products that make a positive contribution to the circular economy (“close the loop” and “extend the loop”) in line with TripleS (Sustainable Solution Steering) Portfolio Assessment.

BASF solutions for the circular economy