Sustainability

Circular Economy

More circular economy, less consumption of fossil raw materials

Raw materials – whether fossil or renewable – are essential for our production and must be used efficiently and responsibly. Ideally, we keep them in the production cycle for as long as possible in order to slow down the consumption of natural resources, thus protecting the environment.

With innovative technologies and the development of circular solutions, we want to generate less waste and thus also consume fewer fossil raw materials. In addition, we want to increase annual sales of these circular solutions, which we call Loop Solutions, from the current level of 5 billion to 10 billion euros by 2030.

Loop Solutions include products that are based entirely or partially on renewable or recycled raw materials or support recycling processes ("close the loop"), as well as products that increase the durability of materials or extend their service life ("extend the loop").

We are striving to transition to a circular economy by focusing on the use of larger quantities of circular raw materials (both recycled and renewable) and by establishing new material cycles and new business models. This requires a new way of thinking – away from value chains, i.e., the linear processes from idea to production to delivery to the customer, and toward value-added cycles, i.e., cyclical, closed processes. BASF teams are currently working on more than 50 solutions to achieve this.

At BASF, we call products that close or extend cycles and thus make a positive contribution to the circular economy "Loop Solutions."

Imagine your favorite jacket, which eventually wears out. Normally, you would throw it away. But what if you could make something new out of it? That's exactly what "extend the loop" is all about: things and materials should not simply end up in the trash after use, but should be used for as long as possible and reused again and again – for example, by making new jackets out of old ones.

The same applies to a sweater that no longer fits or is ruined. Instead of throwing it away, you can collect it, take it apart and make a new sweater from the material. This is called "close the loop." It means that things don't just become trash, but are given a new life. This saves raw materials and is good for the environment.

All in all, these are clever ideas that ensure that our things remain in a cycle for as long as possible instead of becoming waste.

Depending on availability and demand, we feed renewable or recycled raw materials into our production process and can calculate and allocate their share in a specific product. This is called the mass balance approach. To ensure that these allocations are reliable, they are certified by independent third parties.

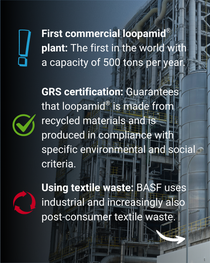

Projects such as loopamid® textile recycling show that circular business models are possible. However, what works in individual projects must also be economically viable on a large scale if we are to move from a linear to a circular economy.

Example 1: Renewable carbon – use of renewable raw materials

At BASF, we want to reduce not only our greenhouse gas emissions but also our dependence on fossil raw materials. By incorporating renewable, organic carbon into our business models and product portfolio, we are creating an important lever for progress in climate protection.

This carbon, whether it comes from plants and animals or microorganisms and agricultural residues, is used to manufacture plastics, fibers and chemicals, for example. This replaces traditional fossil carbon sources such as naphtha, which is based on crude oil.

Here is an illustration of this principle:

Example 2: New material cycle with loopamid®

With loopamid®, we have found a solution for turning old polyamide textiles, including those containing nylon, into new clothing. This creates a new material cycle.

With our help, our partner Inditex has produced a jacket that is made entirely from old clothes, is recyclable and was launched as a pilot product by the fashion company Zara in 2024.

"We need a new mindset"

A successful transition to a circular economy is only possible if we work with partners in different industries to build new economic systems. This requires a new mindset – from thinking in terms of value chains to acting in value cycles.

.jpg)