Ludwigshafen

The current Photo:

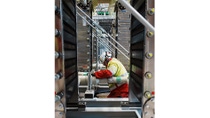

The last few centimeters are done by hand: workers connect up the individual electrolyzer modules. The finished electrolyzer comprises a total of 72 "stacks" with a capacity of 54 megawatts.

First "stacks" delivered for water electrolyzer

The modules known as "stacks" could be said to make up the heart of the electrolyzer. They are currently arriving at the project site in Ludwigshafen almost daily by heavy lorries, and the first of them have already been installed. These modules, produced by Siemens Energy, are where the actual electrolysis process – the splitting of water molecules into hydrogen and oxygen – takes place. As the electricity used comes from renewable sources, the climate-friendly hydrogen produced can be used to manufacture products with a reduced carbon footprint.

When completed, the electrolyzer will comprise a total of 72 "stacks" with an installed power demand of 54 megawatts. Water and gas pipes connect the individual stacks to other components such as heat exchangers, gas separators and rectifiers. The finished system will have a capacity of up to 8,000 metric tons of hydrogen per year and reduce annual greenhouse gas emissions at the site by up to 72,000 metric tons.

The installation of the core modules is one of the major stages in the commissioning of the electrolyzer. Over the coming months, high-voltage transformers will also be installed, and the system will be connected to the infrastructure via pipe bridges, and linked to the hydrogen Verbund network at the site. The plant is scheduled to go into operation in the first half of 2025.

In cooperation with the State of Rhineland-Palatinate, the German Federal Ministry for Economic Affairs and Climate Action is contributing up to €124.3 million to the project – up to €37.3 million of which will be financed by the government of Rhineland-Palatinate.

Further information at:

https://www.basf.com/global/en/media/news-releases/2023/11/p-23-367.html