Ludwigshafen

Contractor Management at BASF

Cooperation based on respectful partnership and the highest standards of safety and quality characterizes the contractor management at BASF.

The employees of contractor management advise contractors, continuously improve collaboration processes and ensure transparent performance assessment so that the efficiency of the contractors is constantly increasing.

Quality and safety have top priority in the cooperation between BASF and contractors. Accidents must be avoided so that each contractor and BASF employee arrives at home safe each day.

How we work together

In order to simplify the work of the contractors at BASF, we have dedicated BASF representatives and mentors who give comprehensive support. On the part of the contractors, respective representatives should ensure efficient cooperation.

BASF representatives are qualified employees of BASF who are entitled to issue orders to contractor officers and to monitor their work.

Mentors are professional employees of BASF's contractor management. They support the contractors from day one and in their further development. They act as intermediates between BASF and the contractors, assess their qualifications and support them - especially with regard to BASF's requirements for safety, health and environmental protection.

The contractor representatives are employees of the contractors who are authorized to accept orders. The contractor representatives also instruct their own employees and monitor their work. This also applies to the employees of subcontractors. The contractor representatives are therefore the main contact persons for customers on the part of BASF and for BASF mentors.

Contractor bases

The contractors can set up their own bases on the BASF site. Most bases are workshops, warehouses, offices or social rooms. The contractors can rent space for setting up bases at BASF, subject to availability.

The mentors regularly inspect these bases and make sure that the contractors have the infrastructure they need at their bases and work in accordance with BASF specifications.

Life-saving rules at BASF

Safety is the top priority at BASF. We always prioritize safety and take responsibility for our personal well-being, that of our colleagues and that of those around us. That is why we have been working at the Ludwigshafen site for decades with basic safety rules that are non-negotiable: the life-saving rules.

Although the rules have been part of BASF's safety culture for a very long time, violations still occur from time to time.

In order to further raise awareness of safety and to get one step closer to our goal of "zero accidents", we have been pursuing compliance with these rules even more consistently since February 2017.

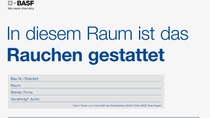

Smoking and open flames prohibited

- The ban applies to the entire factory premises.

- The ban also includes

- any establishment of contractors, such as contractor bases.

- smoking and open flames in vehicles.

- Please note that the smoking ban also applies to e-cigarettes.

- The term "open flames" also includes technical processes that can cause flying sparks.

- The exception: smoking is permitted in designated areas.

- In the agricultural center in Limburgerhof, smoking is prohibited in buildings and marked danger zones.

Alcohol and drugs prohibited on plant premises

- The import, consumption and trading of alcoholic beverages and drugs is prohibited on the factory premises.

- You are also in violation of this rule if you arrive on the premises under the influence of drugs or alcohol in a condition that affects your ability to work.

- Note that you may still be affected even after using it a long time ago. The determination of the impairment of the ability to work is carried out by a company doctor.

- It should also be noted that medication can also lead to a severe impairment of the ability to work. If in doubt, please ask a doctor.

Do not enter marked hazardous areas

- Designated hazardous areas include, among others

- cordoned off operating areas

- security chambers

- Areas of use that are marked during emergency operations, for example by emergency services or "emergency boards"

- appropriately marked roof areas

- The exception: You may enter or drive on marked hazardous areas with a corresponding release. If in doubt, obtain information from the company, for example at the registration office

Removal and bypassing of safety equipment prohibited

- Safety devices are among others

- intrusion protection

- two-hand operation

- light barriers

- safety switch

- barriers

- locks and seals

- security doors.

- Circumventing safety devices, for example during repair work, is only possible with a corresponding operational risk assessment, e.g. a permit.

Hazardous work only allowed with permit

- If there are operational hazards, at least one of the following permits is required: work permit, driving permit, fire permit, permit for earthworks, crane permit for mobile cranes.

- The permits must be filled out in full and signed by the company before the work begins.

- When working with a permit, the authorized person must always be on site. nIn the special case "operating instructions" applies (exclusively for employees of a company): For work that serves to maintain normal operations and is regularly carried out by employees of the company, the work permit can be replaced by operating instructions (prerequisite: regular instruction is ensured) .

- BASF's permit system is regulated in the SHE regulations.

- If there are no operational hazards, this must be documented by the company in a comprehensible manner.

Working at height only allowed with fall protection

- Work at height includes, for example, working on edges, climbing a mast, working on aerial work platforms or working on non-accessible roofs and skylights

- For workplaces, measures against falls are generally required for a fall height of more than one meter. When working on and above water, you must always take precautionary measures against falls, regardless of the height of the fall.

- Protect yourself from a crash by using

- fall protection (e.g. protective scaffolding, protective railing)

- a catchment device (e.g. catch nets) or

- personal fall protection equipment.

- Work on ladders can be carried out without fall protection if there is no risk of falling. This is the case when carrying out light work in accordance with the 3-point rule (two feet and one hand or one foot and two hands on the ladder). Light work is, for example, changing bulbs and installing insulation. In principle, the rules for the safe use of ladders must be observed, please also take into account the safety rules for manual work. (Registration required)

- Work on the loading areas of trailers (e.g. attaching load securing, attaching, directing, setting down and picking up the load) with a height of between 1 and 2 meters may be carried out without fall protection. A climbing aid must be used for this. The employees are required to be particularly vigilant for this activity, physical strain on the employees is to be avoided.

- Exception: Work on the loading areas of trailers (e.g. attaching load securing, attaching, directing, setting down and picking up the load) with a height of between 1 and 2 meters may be carried out without fall protection. A climbing aid must be used to get onto the loading area. The employees are required to be particularly vigilant for this activity, physical strain on the employees is to be avoided.

There is no greater good than our health and physical integrity. Therefore, following the life-saving rules and ensure that they are observed in your environment.

Communicate the rules within your company and to your sub-companies and make sure that those around you follow them at all times. Intervene if you see work being done unsafely or if your colleagues or BASF employees are breaking safety rules. Before starting work and during your job, always ask yourself whether you can do your job safely. If not, stop the work or don't start it at all.

Violation of one of the life-saving rules will be punished with a plant ban of at least one year for the affected contractor employee.

The Ludwigshafen site must be a role model in the chemical industry – also when it comes to safety. This requires our joint commitment. You are part of it.

Infocenter for contractors at site Ludwigshafen

Contractor Manual

The Contractor Award

Access to the site Ludwigshafen

You can find all the documents you need to receive your permanent ID card issued at ID card office J660 and to apply for entry permits at ID cards and authorizations (only in German).

Safety at BASF

Safety is the top priority at BASF. Work on the site can therefore only be carried out with a valid permit. Particular operational hazards and measures to control them are noted in the permit.

Therefore, please inform yourself in detail about the permit system ("Erlaubnisscheinsystem"). This is for your safety and the safety of everyone. Additional documents such as forms and help for permits, instructions and other documents can be found in our infocenter for contractors on site Ludwigshafen (registration required).

You can find the corresponding films and tutorial videos here (registration required).