Dispersions, Resins and Additives

JONCRYL® LMV low-maintenance, acrylic water-based polymer emulsions

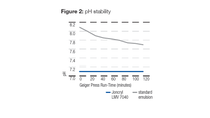

JONCRYL LMV low-maintenance, water-based acrylic polymers for printing inks reduce print waste by providing clean printing and excellent pH stability without sacrificing resistance properties.

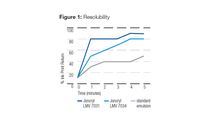

Industry studies show that total press downtime in a flexible packaging operation can be as high as 50%. Of that downtime, 20% is “ink related.” JONCRYL LMV resin solutions and emulsions allow ink makers to offer printers and converters an alternative to current water-based technology and reduce waste and downtime due to anilox plugging and ink build-up on plates. JONCRYL LMV pH-stable polymers, when used to make low VOC inks for paper, film, and foil inks, provide a balance of clean printing, resolubility, and excellent pH stability without sacrificing resistance properties.

Key features and benefits

- Significant cost savings in ink additives and spoiled ink

- Improved pressroom efficiency

- Less print waste

Applications

- Functional packaging

- Overprint varnish (OPV)

- Paper and paperboard